General description of Hydraucyclone desander desitler

Hydraucyclone is a normal parts used for mining industry, for drilling field, for waste water separation, soil depuration. In drilling field. Hydraucyclone can be used as desander desilter per different size. Or combined with shale shaker to work as mud cleaner.

Big size desander cone normally used for mining, piling or CBM drilling. Hydraucyclone for desander desilter in drilling fieldi usually small size:

1) Hydraucyclone for desander: 12inch, 10inch

2) Hydraucyclone for desilter: 5inch, 4inch

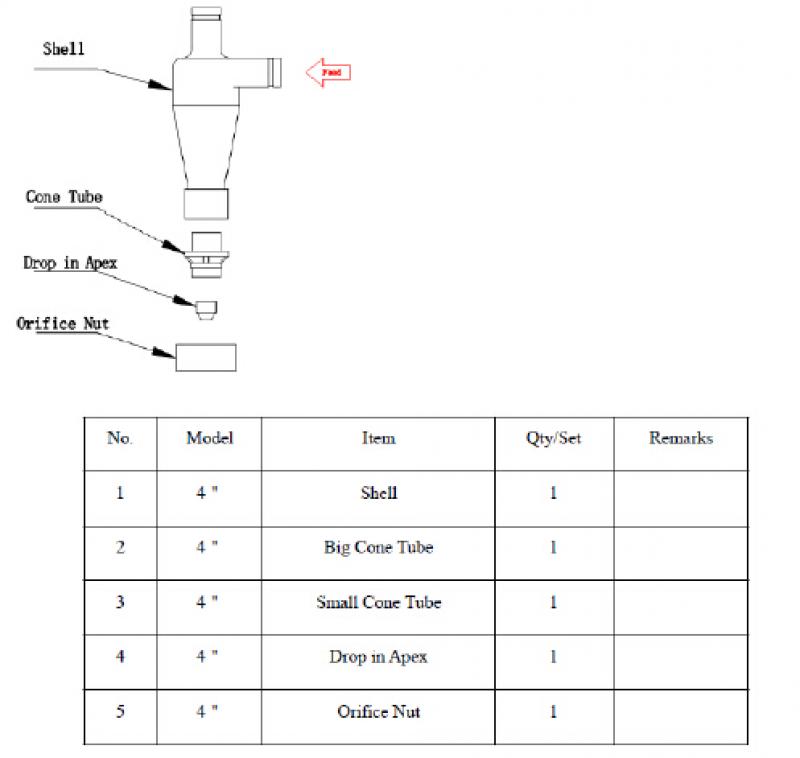

Main parts of Hydraucyclone for desander desitler. Take example of 4 inch desilter cone, it is components of below parts:

1) Shell

2) Cone tube

3) Drop in Apex

4) Orifice nut

When combined for a desilter machine, elbows and clamps, ball valves will be used for connection.

Principle of Hydraucyclone for desander desitler

Hydrocyclone is a cylindrical part of the conical vessel. The upper part of the internal cone section called the liquid cavity. Cone outside is provided with a liquid inlet pipe, and the liquid cavity is communicated to the tangential direction. The top of the container is the overflow port, the bottom is underflow (also called the discharging port). Cyclone size is determined by the maximum diameter of the cone. Its working principle is centrifugal sedimentation. Because of the coarse particles and fine particle size difference exists (or density difference), the centrifugal force, under the centripetal buoyancy, drag force of different sizes, due to the centrifugal sedimentation, pyramidal intermediate creates a low pressure area, forming a column of air, caused by vacuum suction effect, play, most of the fine particles in the cyclone under the actions of upper discharged from the overflow tube, heavy particles thrown to the wall of the barrel, slide along the barrel wall, from bottom outlet.

Materials ofd Hydraucyclone for desander desitler

Polyurethane is also called polyurethane formate, is a kind of polymer between the plastic and the rubber polymer materials. It has not only high strength plastic, and has the high elasticity of rubber. It is a new type of wear resistant material, an excellent comprehensive performance. It has many excellent performance, high wear resistance, in the synthetic material of the first, even more than some alloy steels. The polyurethane as hydrocyclone lining, its service life is four times of high chromium cast iron, four times eight times Ding hydrogen rubber, natural rubber. Polyurethane shore hardness in the range of 17~97 to 85~90, the best wear resistance.