Mongoose series shaker screen is designed by Mi-Swaco for its Mongoose series shale shaker. Orinial, it is composite material screen for Mongoose shaker.

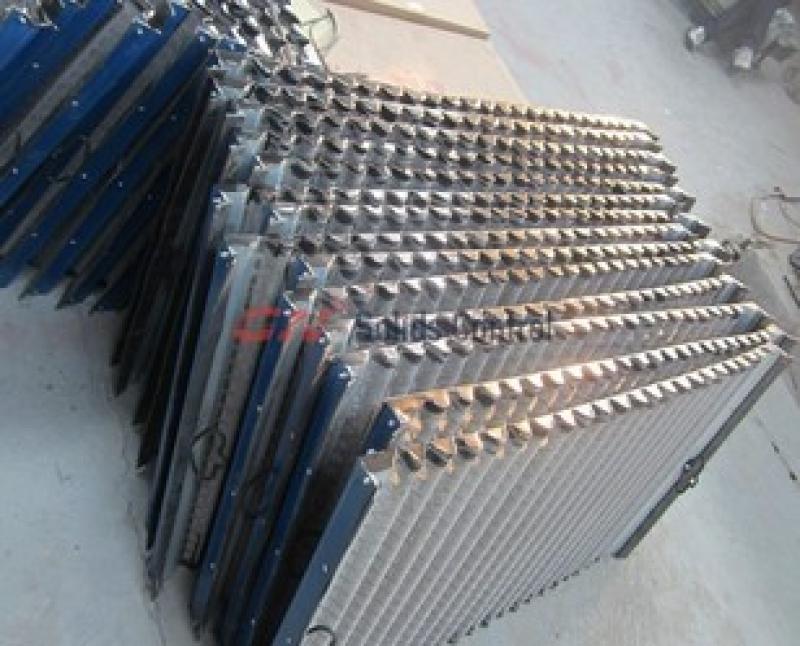

For saving cost in some cases, there is common pre-tensioned steel frame screen for option. The steel frame Mongoose screen and composite Mongoose screen both suits well on Mongoonse shaker.

Difference of Composite Swaco Mongoose screen & steel frame screen

Composite frame screen have longer service life, better appearance, and convenience on operaion.

Price of the composite material screen are higher than steel frame, usually more than double.