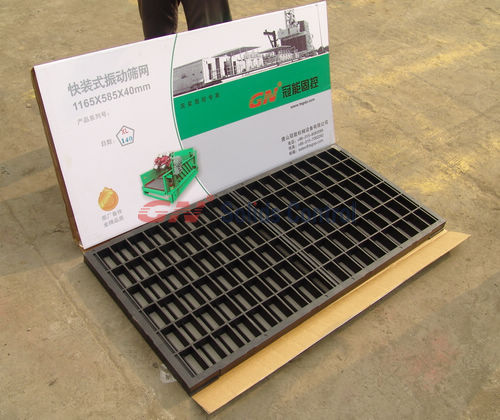

Many clients request make shaker screens per API standard, and screen label and tag format should be accordance with API RP13C.

World top screen manufacturer – GN Solids Control do international market well and know international market standard well.

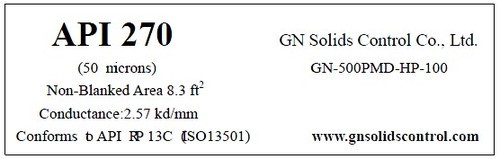

The manufacturer may use two screen tags on the screen panel in order to include supplemental information deemed necessary provided that:

1) the style of font remains identical on all screen tags;

2) the API Screen Designation is displayed on the same tag as the manufacturer’s screen designation;

3) the size of the API Screen Designation is at least twice the size of the manufacturer’s screen designation;

4) all information contained with the screen designation system may be of a single, legible font style of manufacturer’s choosing.