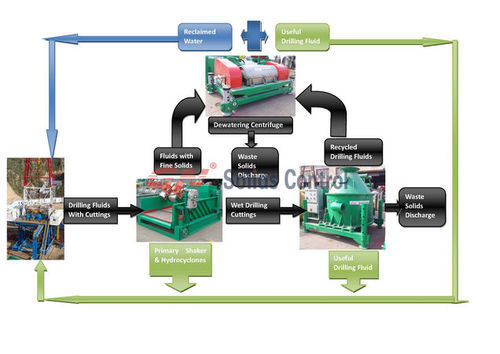

Shaker screen is the most expensive wearing parts of shale shaker, even for the whole rig operation ,it is not a small cost.Why say so?

You see,if a rig matched with 3 shakers,1 shaker with 3 screen panel,totally 9 pcs shaker screen, every month min. 27 pcs screen while drilling. Cost for 1 year is a big amount.

Why chooses GN brand shaker screen?

GN shaker screen price is 20~30% of Derrick screen;

GN shaker screen lifetime is 80% of Derrick screen;

Totally, GN shaker screen cost is 30~40% of Derrick screen.